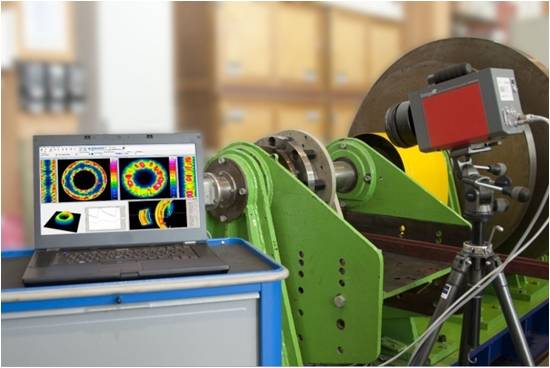

IRBIS rotate高速旋转部件热特性红外成像检测分析系统

-

-

提高轮胎、制动碟片、离合器、砂轮、轮轴以及发动机叶片等容易磨损部件的质量和使用寿命一直为人们所关注。 InfraTec因应市场需求开发了高速旋转部件热特性红外成像检测系统IRBIS® 3 rotate。该系统可以高效率的同步测量、记录和分析旋转部件在高转速和不同压力条件下的正面和两侧壁面的热特性。IRBIS® 3 rotate具有自动触发启动、实时动态红外热图可视、现场即时分析相关数据、连续数据采集和存档等功能。

IRBIS® rotate高速旋转部件热特性红外成像检测系统可以用来高效率的同步测量、记录和分析制动盘、离合器和轮胎等高速旋转目标物体在不同压力条件下正面和双侧壁面的热特性。IRBIS® 3 rotate具有自动触发启动、实时动态红外热图可视、现场即时分析相关数据、连续数据采集和存档等功能。

-

非接触的方式在线采集热分布状态

-

高速线扫描模式速率达13KHz

-

带有原始图像和角度位置的两侧和正面数据的同步采集 / 合并

-

自动热点检测

-

过程信号界面接口 (触发输入、报警和测量值输出)

-

外部机器参数 (速度,接触压力)直接记录

-

回放功能

-

采集参数可以调整和保存

-

当超过临界温度阈值报警

-

Irbis 3Rotate 和 Professional专业数据处理和分析软件

-

红外热像仪也可作为单机使用,完成温度测量和外热图采集

Rotational Test Benches Made by InfraTec

The automotive industry's wearing part requirements concerning lifetime and quality are increasing steadily. To investigate rotational parts, such as brakes and clutches under different load conditions, InfraTec GmbH has developed an IR-rotation test system. The test object will be sampled at sample rates which range up to the kilohertz band. Data acquisition will be triggered automatically by the testing machine. Various transformations can be done to display and archive the thermographic data. The thermography evaluation software IRBIS® 3 rotate is available to analyse the acquired data.

-

Advantages of the Evaluation Software IRBIS® 3 rotate

-

Automatic hotspot detection

-

Alarm function against transgression of critical temperature limits in a live load test

-

Measurements in various transformation views

-

Synchronous crude data acquisition

-

Online display during the test

更多详细信息,请至英文网页High-speed Rotation Test Bench - TRC

-

-